Efficient Electric Motors: Improving Reliability and Energy Efficiency in Industrial Equipment

Learn how efficient electric motors and intelligent motor control improve reliability, reduce energy use and support smoother restarts after downtime.

Contact Hyspecs

Efficient motors: Small improvements that deliver big gains

When machines return to service after extended downtime, electric motors are often expected to perform at full capacity immediately. But efficiency losses can creep in quietly, especially after weeks of inactivity, changing loads or evolving operating demands.

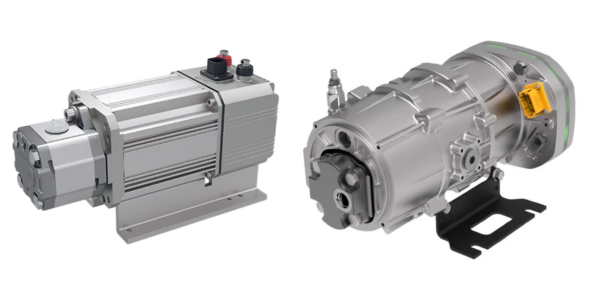

With modern motor technology and advance materials, more efficient motors can be constructed, improving Machine reliability, reduce energy consumption and extend equipment life, without major mechanical changes. Some of these motors can reach up to 98% efficiency.

Why motor efficiency matters

Electric motors are one of the largest energy consumers in industrial equipment. Even modest efficiency improvements can result in meaningful cost savings over time, while also reducing heat, wear and unplanned downtime.

From a reliability perspective, efficient motors tend to run cooler, draw less current and place less stress on switch gear supplying these motors. This directly supports longer service intervals and more predictable performance.

For operations teams, this means fewer breakdowns and better control over operating costs.

Intelligent motor control and optimisation

Solutions such as Hydrapulse (Terzo), Danfoss Editron, ePanda systems are designed to deliver higher efficiency through smarter electrical design and precise control.

Rather than simply supplying power, modern motor systems actively manage speed, torque and load to match real-world operating conditions. This reduces wasted energy during low-load or variable-duty cycles, which are common in many industrial and mobile applications.

In practical terms, this can mean:

- Lower energy consumption during normal operation

- Reduced peak current draw on startup

- Improved response and smoother operation

- Less heat buildup in motors and cabling

Matching the motor to the job

One of the most common causes of inefficiency is motor oversizing or mismatched control systems. Equipment may run reliably, but far from optimal.

Another big mistake is looking at the cheaper products, they tend to be less efficient and will add up on the electrical bill in the long run, cancelling out the initial saving.

By reviewing motor selection, control strategy and duty cycle, it’s often possible to achieve efficiency gains without replacing entire machines. In some cases, upgrades to motor controllers or drive systems deliver immediate improvements in performance and operating cost.

This approach is particularly valuable when bringing older or intermittently used equipment back into service after shutdown periods.

Supporting reliability as operations ramp up

As machines restart after a long break, now is an ideal time to assess whether motors are still fit for purpose. Early checks and targeted upgrades can prevent issues later in the production cycle, when downtime is far more disruptive.

Efficient motor systems don’t just save energy. They support smoother startups, reduce electrical stress and help equipment operate consistently as workloads increase.

At Hyspecs, our electrical team works with proven technologies like Hydrapulse (Terzo), Danfoss Editron and ePanda to help customers improve efficiency while maintaining the reliability their operations depend on.