EPE Hydraulic Accumulators – Energy Storage Solutions for Reliable Hydraulic Systems

Discover EPE hydraulic accumulators from Hyspecs engineered for safety, efficiency and performance.

Contact Hyspecs

EPE Hydraulic Accumulators: Smarter Energy, Smoother Systems

In hydraulic systems, performance depends on how well energy is stored, managed and released. That’s where accumulators make all the difference. Italian-made EPE accumulators are engineered for reliability, safety and efficiency, helping extend system life and improve response times across everything from mobile machinery to industrial automation.

At Hyspecs, we supply and service the full range of EPE bladder, piston and diaphragm accumulators, giving our customers the confidence that their hydraulic systems are performing at their best. Designed to meet international standards (including PED 2014/68/EU and AS 1210 for pressure vessels), EPE accumulators deliver consistent performance in demanding New Zealand and Australian environments from forestry and construction to marine and manufacturing.

How Hydraulic Accumulators Work

A hydraulic accumulator stores potential energy in the form of pressurised fluid. When system demand increases, the accumulator releases that energy instantly, maintaining pressure, absorbing shocks and ensuring smooth operation.

Inside an accumulator, a gas (usually nitrogen) is compressed by hydraulic fluid. As the pressure in the system changes, the gas expands or contracts to balance flow and maintain pressure stability. This simple but powerful principle makes accumulators a key part of almost every modern hydraulic circuit.

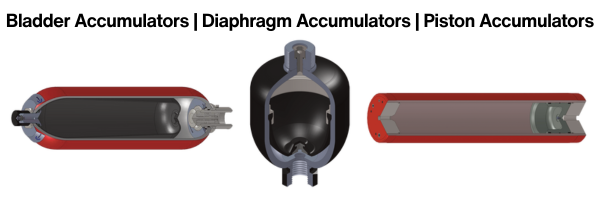

Types of EPE Accumulators

EPE produces several accumulator types, each suited to different system requirements:

- Bladder Accumulators

The most common type. A flexible bladder separates the gas and hydraulic fluid, offering quick response times and excellent energy storage. Ideal for mobile equipment, lifting systems and general hydraulic applications.

- Diaphragm Accumulators

Compact and cost-effective, diaphragm units are well-suited for smaller circuits, dampening pulsations and maintaining pressure in compact hydraulic systems.

- Piston Accumulators

A robust design using a floating piston to separate gas and fluid. They handle higher volumes and pressures, making them perfect for heavy-duty or industrial systems such as presses, marine hydraulics and injection moulding machines.

Each EPE accumulator is manufactured and tested in Italy to meet international safety and performance standards, with materials and seals compatible with a wide range of hydraulic fluids.

Benefits of Using EPE Accumulators

- Energy efficiency: Store excess energy and release it when needed, reducing pump load and energy consumption.

- System protection: Smooth out pressure spikes and absorb hydraulic shock, protecting pumps, valves and actuators.

- Improved performance: Maintain stable system pressure and enhance responsiveness during peak demand.

- Extended component life: Reduce wear and stress on hydraulic components by stabilising pressure fluctuations.

- Compliance and safety: Built to international standards and supported by local testing and certification.

Why Choose Hyspecs for EPE Accumulators

Hyspecs is the authorised distributor and service partner for EPE hydraulic accumulators in New Zealand and Australia. Our team of engineers can:

- Select the right accumulator type and size for your application

- Pre-charge and test units to specification

- Provide AS1210-1997 (a revision of the AS 1210 standard) and compliance documentation

- This revision of the AS1210 standard which allows for increased pressure ratings of various accumulators due to improvements in material strengths

- Perform inspection, recharging, and bladder replacement services

- Support full accumulator system design and integration

Whether you need a replacement accumulator, a complete system upgrade or ongoing maintenance support, Hyspecs can deliver the right solution built to last.

For expert advice on sizing, selection or servicing of EPE accumulators, contact your local Hyspecs branch. Our engineering team will help ensure your system runs smoothly, efficiently and safely every time.