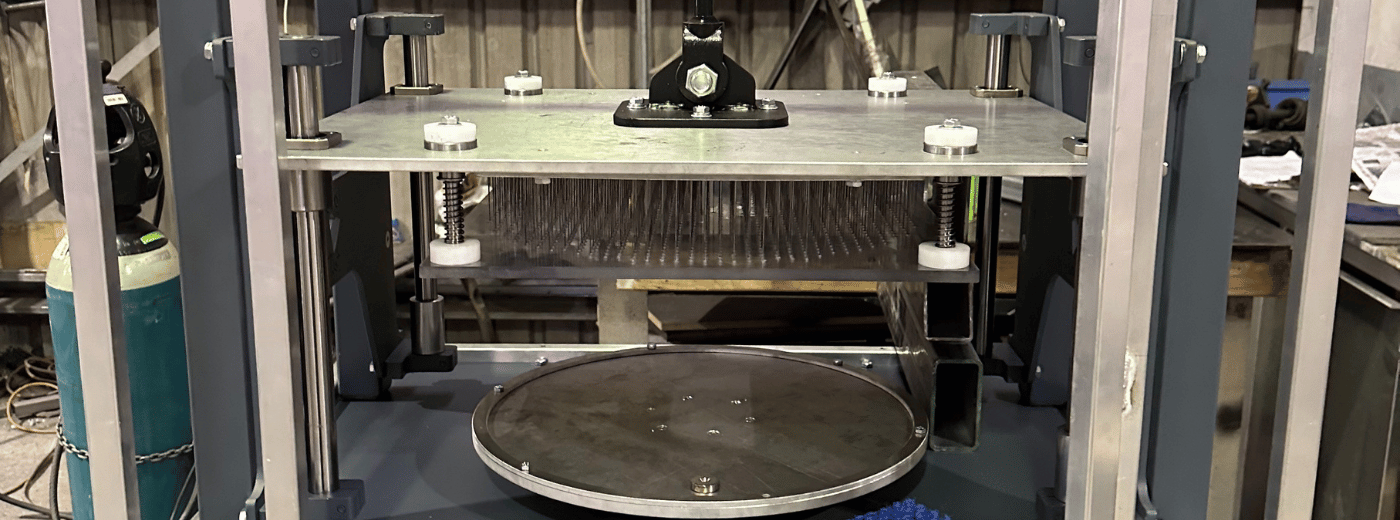

Automating Artisan Production: Custom Hydraulic System for Needle Felt Press

Hyspecs supplied the precision hydraulic components for a new needle felt press in Central Otago, enabling the smooth, automated upgrade of a previously manual artisan process.

Contact Hyspecs

In Central Otago, a local craftswoman hand-makes felted wool cushions each one a bespoke piece. Until recently, her pressing process was fully manual, time-consuming and physically demanding. Seeking improved efficiency, she partnered with a local engineering team to design an automated needle felt press and Hyspecs was selected to deliver the hydraulic control system.

This project was delivered in collaboration with Central Custom Engineering, who managed the automation and mechanical integration on-site in Central Otago.

Hydraulic Solution Supplied by Hyspecs:

- 5kW Modular Power Pack (drawing less than 10Amp)

- Pressure to tank relief valve (adjustable from 4–41 bar / 50–600 psi)

- Electric load holding module to eliminate cylinder drift

- Cetop 3 electric directional control valve

- Double acting cylinder

- Factory-assembled and tested for plug-and-play deployment

The client was particularly impressed by the quiet, controlled operation and precision adjustability of the pressure. The machine now delivers consistent pressing force and a reliable production rhythm that far surpasses the previous manual method.

Performance at a Glance:

- Extension Force: 50–480kg (adjustable via relief valve)

- Extend Speed: 150 mm/sec

- Retract Speed: 195 mm/sec

This project demonstrates how Hyspecs enables custom automation upgrades, even in low-volume, artisanal production settings, combining industrial-grade reliability with tailored control.